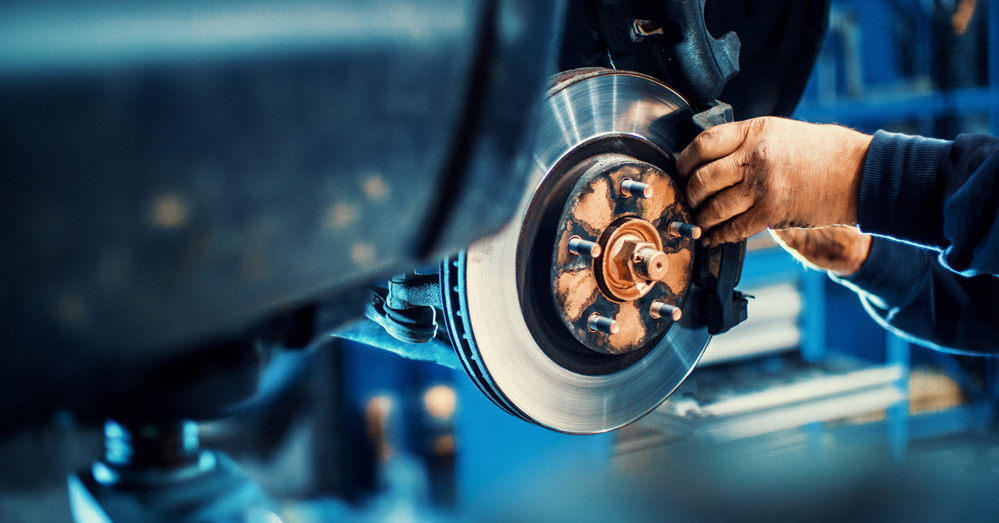

How to choose brake pads

The performance of the braking system of any car is the most important factor that has the most direct impact on road safety. It depends not only on the timely replacement of technical fluids and brake discs, but also on the state of the brake pads, the quality of their performance and on how well the pads perform the functions assigned to them. In order to minimize the risk of an abnormal situation, careful attention should be paid to the choice of shoes.

We recommend reading the article from an expert on brake disc selection and top secrets brake fluid selection for cars.

Top Brake Shoe Manufacturers

Among motorists there was a clear gradation of brands that produce brake pads, which depends on the quality and on the price that you have to pay for it. The best products are the following brands:

-

ATE;

-

Brembo;

-

TRW;

-

Pagid;

-

Ferodo;

-

Zimmerman;

It should be remembered that the functionality of the pads of the same manufacturer can be quite different depending on the model of the car and its power, and therefore it is necessary to study user reviews and their tips on choosing the pads for a particular car. You can find them on the Internet, on all sorts of subject forums and social networks.

Types of brake pads

The principle of brake pad operation is based on the friction interaction of a special multicomponent composition with a metal brake disc. The pads are installed in the caliper and, thanks to the hydraulic system, compress the brake disc evenly on both sides. There are the following types of brake pads.

Organic brake pads

Cheap models whose friction layer is made from organic materials, Kevlar and polymer resins. They have a high coefficient of friction, and therefore slow down the car well. Due to increased softness, they are subject to rapid wear and require replacement after 30–35 thousand kilometers after replacement.

Virtues

-

Inexpensive;

-

Effectively inhibit;

-

Perfectly keep the temperature;

-

Soft;

disadvantages

-

A large number of wear products;

-

When moisture gets between the disc and the pad, the braking performance deteriorates many times;

-

Quickly erased;

Virtues

-

Inexpensive;

-

Effectively inhibit;

-

Perfectly keep the temperature;

-

Soft;

disadvantages

-

A large number of wear products;

-

When moisture gets between the disc and the pad, the braking performance deteriorates many times;

-

Quickly erased;

Metal brake pads

The friction composition is similar to organic models, however, these models have a significant percentage of copper or steel in the composition. This allows you to improve braking performance, improve grip properties and increase the service life of the pads.

Virtues

-

Effective braking;

-

Increased service life;

-

High temperature resistant;

-

Excellent combination of price and quality;

disadvantages

-

Metal leads to rapid wear of the brake disc;

-

More expensive than organic analogues;

-

"Float" after 2-3 braking from high speed (150 and above);

-

During operation, friction materials stand out;

Virtues

-

Effective braking;

-

Increased service life;

-

High temperature resistant;

-

Excellent combination of price and quality;

disadvantages

-

Metal leads to rapid wear of the brake disc;

-

More expensive than organic analogues;

-

"Float" after 2-3 braking from high speed (150 and above);

-

During operation, friction materials stand out;

Ceramic brake pads

The most advanced models, popular among fans of powerful and sports cars. The friction layer includes the minimum amount of steel, but is rich in ceramics, polymeric materials and various non-ferrous metals. As a result of this material, the pads perfectly withstand heat and are not afraid of sudden braking and dynamic driving; braking performance does not decrease in wet weather.

Virtues

-

Brakes better than other models;

-

Do not grind the brake disc;

-

Long service life;

-

Minimum wear products;

-

Efficiency is not lost after several brakes;

disadvantages

- High price;

Virtues

-

Brakes better than other models;

-

Do not grind the brake disc;

-

Long service life;

-

Minimum wear products;

-

Efficiency is not lost after several brakes;

disadvantages

- High price;

Brake pad selection options

Type of fastening friction material to the base of the block

-

Glued pads. The surfaces are connected using a special adhesive layer. Greater resource and braking uniformity. The disadvantages include the probability of damage to the brake disc in case of complete abrasion of the friction layer;

-

Rivet pads. The friction layer is attached to the base with a few rivets. The disadvantages are uneven braking and the appearance of vibration on the steering wheel during active driving. The resource of such pads is approximately the same as that of the glued ones;

The quality and condition of the support plate

The appearance of the substrate can say a lot. Quality pads have a uniform plate of the same thickness, devoid of bends and irregularities. The friction material should be fixed evenly over the entire surface of the pad and not peel off from it.

Coefficient of friction of the working surface

A parameter that takes into account frictional characteristics and indicates braking efficiency. The higher this parameter - the faster the car will stop. Preference should be given to the pads, the value of which is at the level of 0.6-0.7 and above.

Preference should be given blocks, the value of the coefficient of friction is at the level of 0.6-0.7 and above.

Heat Resistance Pad

The parameter that displays the performance of the pads in extreme conditions. The higher this value is, the better the brake will work. system in extreme operating conditions. The best in this regard are ceramic pads, the working temperature of which is 700-900 degrees. However, it makes no sense to install them on low-powered civilian engines - their potential is revealed only at speeds of 150 and above, as well as with frequent and abrupt locking. In the latter case, high-quality metal pads with a working temperature of about 400-450 degrees, more than enough.

Presence of wear sensor

Even budget cars are currently equipped with a variety of different sensors, one of which is a brake pad wear sensor. It shows the percentage of residual friction material and signals the need to replace the pads on the dashboard. If the car is equipped with a similar system, you should choose the pads, providing work with this sensor and having a slot for the location of the sensor itself.

In the next article, we tell you how. choose alloy wheels for car. The main criteria for selecting quality discs. Popular manufacturers and more.

Attention! This material is the subjective opinion of the authors of the project and is not a guide to purchase.