How to choose a cabin filter

The cabin filter is a special element designed to clean the air entering the cabin from dust, mechanical impurities, as well as all kinds of gases and odors. Properly selected filter plays an important role not only in ensuring the comfort of the passengers of the car, but also in the correct functioning of air conditioning systems and climate control.

We recommend reading the article from an expert on air filter selection and secrets engine oil filter selection.

Top manufacturers

Preference should be given to well-known European brands that produce high-quality models, whose products are installed in well-known car brands in the factory:

-

Mann;

-

Knecht;

-

Filtron;

-

Hegnst;

-

Mahle;

In order to choose the optimal model for a particular car, it is necessary to examine the range of the catalog of the manufacturer of interest, as well as get acquainted with thematic user reviews at specialized automotive sites. It is in the latter that one can find many practical advice on how to extend the service life and ensure maximum filter efficiency.

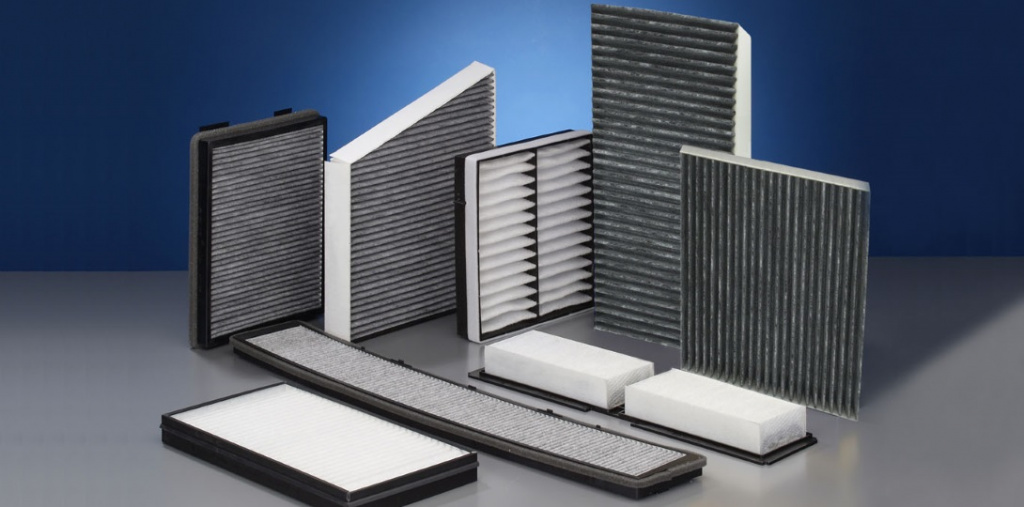

Types of cabin filters

Despite the seeming simplicity of the cabin filter design, models of this class can be quite noticeable in terms of functionality. First of all, it is connected with the type of material, as well as with the technology used in its manufacture. In this regard, the following types of "salons" are distinguished.

Barrier filters (paper)

Simple and inexpensive models, the manufacture of which used cellulose with the addition of synthetic materials. Used to protect passengers from dust, exhaust gases, poplar fluff and other irritants. Sensibly quench odors and do not contribute to the absorption of moisture.

Virtues

-

Inexpensive;

-

Steal odors;

-

Protect from dust, poplar fluff, exhaust gases;

disadvantages

-

Subject to burning;

-

Quickly become useless;

Virtues

-

Inexpensive;

-

Steal odors;

-

Protect from dust, poplar fluff, exhaust gases;

disadvantages

-

Subject to burning;

-

Quickly become useless;

Carbon filters

They are made of synthetic filter material with the addition of fine activated carbon. Prevent the penetration of dust and debris into the cabin, as well as perfectly adsorb unpleasant odors and harmful substances. Service life is higher than that of similar models of barrier filters.

Virtues

-

Protect from dust and debris;

-

Do not sustain combustion;

-

Long service life;

-

Adsorb harmful substances and odors, preventing them into the cabin;

-

Do not absorb moisture;

disadvantages

-

More expensive counterparts;

-

Require careful monitoring of the condition;

Virtues

-

Protect from dust and debris;

-

Do not sustain combustion;

-

Long service life;

-

Adsorb harmful substances and odors, preventing them into the cabin;

-

Do not absorb moisture;

disadvantages

-

More expensive counterparts;

-

Require careful monitoring of the condition;

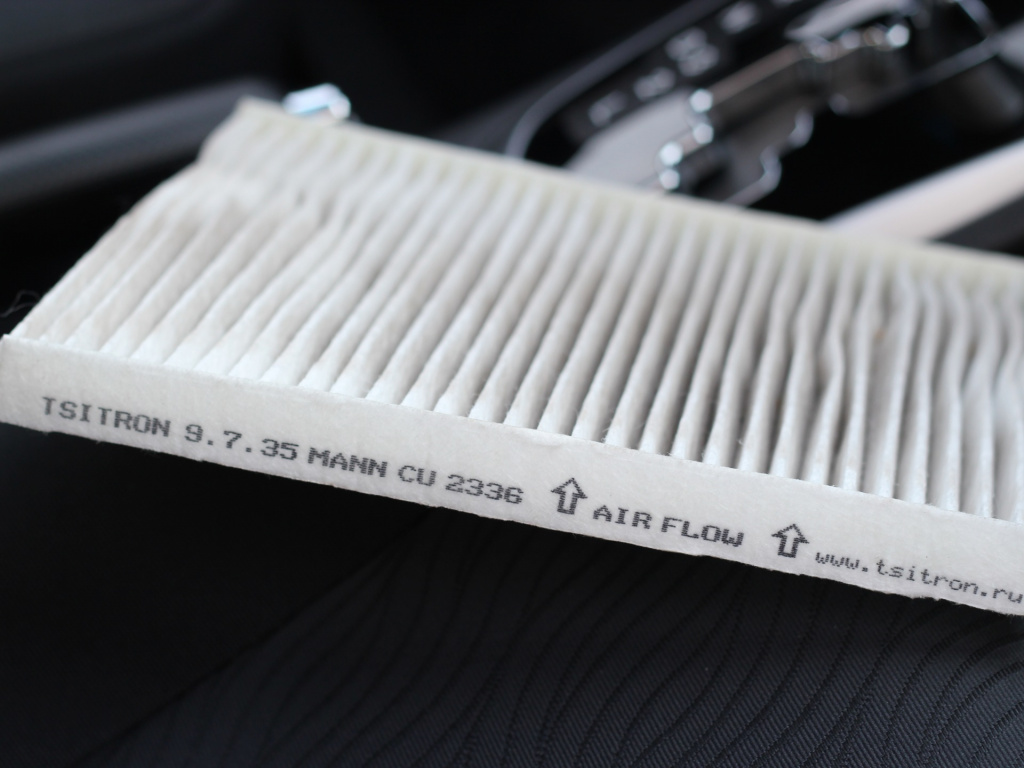

Cabin Filter Selection Parameters

Despite the fact that there are fewer criteria for a high-quality cabin filter than oil or fuel analogues, it is necessary to pay attention to the following technical features and nuances:

-

Workmanship. Properly chosen cabin filter should have the maximum quality of manufacture, the uniform distribution of the filtering material and be deprived of places of rupture and other defects.Each such nuance of the design is a potential weak link contributing to the deterioration of functionality, and therefore external inspection is the first thing that the choice of filter should begin with.

-

Filter weight It is known for certain that the heavier the coal cabin filter is, the more small fractional activated carbon is in it. This, in turn, allows us to talk about more functionality and better cleaning of the air entering the salon;

-

The quality of the frame and compliance with the seat of the car. Inadequate quality filters are installed loosely, forming slots and openings around the perimeter. They will pass dust, dirt and unpleasant smells inside the cabin. In order for this not to happen, the filter must be inserted with effort into the seat and exactly follow its contours;

-

The presence of the laminated layer on the reverse side. Due to the fact that the filter material is a dense fleecy structure, the mechanical elements of the heater motor must be protected from the blown pile. It is for this purpose that the lamination coating on the inside is used;

-

Dust transmission coefficient Parameter reflecting the percentage of dust to the volume of air passing through the filter. According to European quality standards, should be no more than 8-10 percent;

-

Coefficient of aerodynamic drag. Shows how well the filter passes air mass and how much it prevents the passage. Measured in millimeters of water. The value of this coefficient in the new filter is 40-50 mm. waters Art., which has fallen into disrepair after operation, the element passes air several times worse, about 150-200 mm. waters Art.

Attention! This material is the subjective opinion of the authors of the project and is not a guide to purchase.