How to choose a saw blade

The speed and quality of cutting, as well as the presence or absence of scrap and the total amount of waste depend on how well the selected saw blade corresponds to the material being processed. Different types of wood and other materials require the use of various discs, and therefore, before you begin work, you need to be fully armed.

content

- Top drives for cutting wood and circular saws

- Types of saw disks

- Saw blade selection options

- Features of the choice of a saw disk on a tree

- Features of the choice of a saw disk for a circular saw

Top drives for cutting wood and circular saws

When buying saw blades, the choice should be given in favor of high-quality and well-known manufacturers of joinery tools:

-

Bosch

-

Makita

-

Hitachi

-

Dewalt

-

Blaucraft

Characteristics of specific models, as well as customer reviews, can be studied on the Internet, in thematic forums and in social networks. Very often this information becomes decisive for the buyer.

Types of saw disks

Saw blades are called special cutting wheels designed for use in various joinery techniques. Depending on the manufacturing technology, all saw blades are divided into several types.

Monolithic saw blades

Made of solid metal and subjected to the initial laser sharpening. They are almost always based on high-carbon steel, which is distinguished by maximum strength and reliability. Such discs are inexpensive and easy to operate, and also allow sharpening if necessary;

Virtues

-

Low price;

-

Allow secondary sharpening during operation;

-

Durable and sharp;

-

High quality;

disadvantages

-

Quickly dull;

-

Wear with hard surfaces;

Virtues

-

Low price;

-

Allow secondary sharpening during operation;

-

Durable and sharp;

-

High quality;

disadvantages

-

Quickly dull;

-

Wear with hard surfaces;

Carbide wheels

Composite models, the core of which is made of alloy steel, and the cutting edge is a soldering of high strength tungsten or titanium. As a result, this design is distinguished by its low weight, very sharp teeth, and the ability to hold sharpening perfectly.

Virtues

-

High strength;

-

High-quality execution;

-

Excellent hold sharpening even when working with hard surfaces;

-

Sharpness;

disadvantages

-

Expensive;

-

In a frenzy, it is almost impossible to regain the initial acuity;

Virtues

-

High strength;

-

High-quality execution;

-

Excellent hold sharpening even when working with hard surfaces;

-

Sharpness;

disadvantages

-

Expensive;

-

In a frenzy, it is almost impossible to regain the initial acuity;

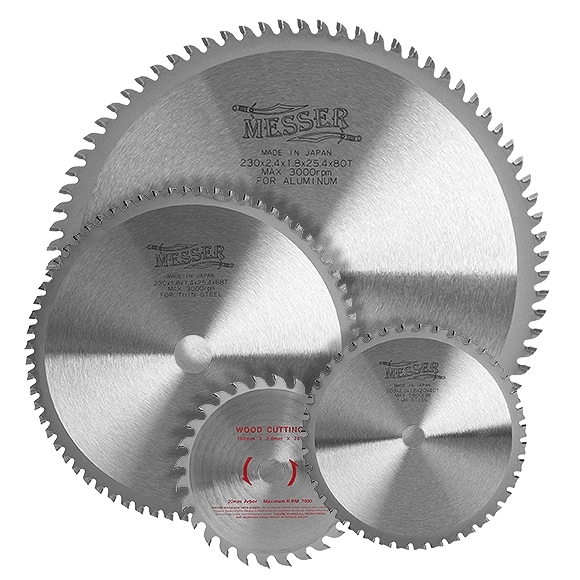

Saw blade selection options

External and fit disc diameters

It is necessary to select those models, the characteristics of which fully fit the specific conditions of use and equipment used. The bore diameter should correspond to the dimensions of the shaft of the cutting device, while the outer diameter should be slightly smaller than the mounting socket;

Number of teeth

-

Disks with a small number of teeth are considered rough, they give a rough cut, but they take the chips from the sawing zone well. A typical number of teeth of a rough disc is from 10 to 40;

-

A large number of discs, from 60 to 90, teeth - clean, designed to perform accurate and accurate cutting of wood;

Tooth shape and size

-

Homogeneous teeth of direct shape are used for processing plywood, chipboard and even aluminum;

-

Heterogeneous teeth, bent away from the centerline in different directions, are designed for cutting soft and hard woods, as well as fiberboard and particleboard;

-

Small trapezoid teeth are designed for cutting soft metals and plastic;

-

Large teeth and a big step between them - a sign of discs for longitudinal cutting of solid solid wood;

-

Small and frequent teeth - direct evidence of a circle designed for cross-cutting;

Disc thickness

The parameter that determines the thickness of the cutting line. The standard disk thickness is 3.2 millimeters, however, both thinner and thicker models can be found on the market. The first are widely used for cutting valuable wood. The second - for working with laminate and various metals;

Features of the choice of a saw disk on a tree

The correct saw blade for wood should have the following characteristics:

-

Monolithic construction;

-

30-40 teeth for a rough saw and 60-80 for getting a smooth finishing seam;

-

Disk thickness - 2.8-3.2 millimeters;

-

The design of the teeth of a heterogeneous shape, each of which is deflected at an angle of 7-9 degrees from the vertical;

-

Planting and outer diameter, corresponding to the dimensions of the device;

Features of the choice of a saw disk for a circular saw

-

Disc structure - carbide;

-

The number, size and structure of the teeth are selected on the basis of the need to work with specific materials and type of wood. More delicate work requires thin discs with a large number of teeth, the execution of a rough saw allows the use of a thicker circle with a small number of large teeth and a significant step between them;

-

The diameter of the disc and the size of the mounting hole are matched to the dimensions of the specific device;

-

Thickness - 3.2 mm or more;

In the following articles, our experts tell how to choose a welding machinesecrets selection of masks for welding and features laser level selection.

Attention! This material is the subjective opinion of the authors of the project and is not a guide to purchase.