How to choose a grinder for your home - expert advice

For a long time, operations with metal and wood in hard-to-reach places caused a lot of problems, difficulties and inconsistencies. Traditional methods to achieve acceptable results did not work and manufacturers went to all sorts of tricks. It was their result that the angle grinder, which the Japanese company Makita invented in the late fifties of the last century, was born. Since then a lot of water has flowed; In our country, these devices are well known by another name - Bulgarian.

content

- What are the Bulgarians - types

- The main criteria for the selection of grinders

- What functions can be equipped with angle grinders?

- Ease of use and weight of the power tool

- What nozzles (disks) are equipped with grinders

- Video on the choice of the grinder

What are the Bulgarians - types

All models of Bulgarian presented on sale can be divided into two conditional categories. Conditional - because, depending on the technical features and the applied solutions, one or another model can be attributed to two classes at the same time:

-

Compact one-handed LBM. They are also often called household, because it is in everyday life that they find their main use. They are characterized by the presence of an electric motor of low power (up to 1.2-1.5 kW), and a disk with a diameter of up to 150 mm is used as a working tool;

-

Professional grinders with two-handed design. The powerful devices intended for long performance of routine work. Their power can reach 3 kilowatts, and the diameter of the installed disk can be 250-300 millimeters. Devices of this class are perfect for working with all materials and types of surfaces;

The main criteria for the selection of grinders

Size of disc used

The disk is a removable cutting disc, which is fixed on the rod of the grinder and makes direct contact with the surface to be treated. The diameter of the cutting wheel varies from 110 to 260 millimeters, and the larger the disc, the harder and more powerful the grinder will be.

We recommend reading the article how to choose a drive for the grinder.

Bulgarian power

By this parameter, the power of an electric motor installed on a device is almost always meant, and with it the functionality of a particular Bulgarian. On sale you can find a large number of different models - starting with compact low-power models (300-400 W) and ending with professional power machines, the power of which exceeds the above mentioned by 7-8 times. The more powerful the LBM is, the more versatile it is, as well as the larger, heavier and, accordingly, more expensive.

Disk rotation speed

In this situation, the initial diameter of the used disk has the most direct effect.Models designed to work with compact discs with a diameter of 110-130 millimeters can develop up to 10-11 thousand revolutions per minute, while larger machines equipped with larger discs are almost never faster than 6.5-7 thousand revolutions per minute. a minute When this threshold is exceeded, parasitic vibrations almost always appear, which lead to the destruction of the disk. The compromise option is the use of angle grinders, equipped with the ability to adjust the speed depending on the type of disk installed, but almost always these machines are quite expensive.

What functions can be equipped with angle grinders?

-

The possibility of a smooth start, eliminating the increased load on the rotor, and the same smooth braking of the device - when the power is turned off, the spindle rotates by inertia for some time;

-

The protective mechanism, which prevents jamming of the circle during cutting. Measures the deviation of the angular velocity of rotation of the circle relative to the original version, and if it reaches a critical value - the Bulgarian automatically turns off;

-

Prevent secondary device startup. a very useful function that prevents the device from starting spontaneously after the voltage in the working network has disappeared. In order to turn on the grinder, you must once again press the start button;

-

Speed controller and speed synchronizer. Highly demanded features, significantly expanding the range of use of Bulgarians. The first allows you to adjust the revolutions of the device and adjust them to the type of disc used, the second serves to maintain sensitively tuned revolutions in any operation mode;

-

Setting the controls "by itself". The location, length, arm departure, as well as many other settings - all this makes working with the grinder as convenient as possible;

Ease of use and weight of the power tool

In order that the Bulgarian was the most convenient and functional, it is necessary to pay special attention to its weight and dimensional characteristics, as well as to such a parameter as balance. The weight of household Bulgarians is almost always limited to 1.5-2 kilograms, while professional models can weigh twice and even three times more. But even with such a rather small weight, it is possible to use angle grinders with a sufficient degree of comfort. All that is needed for this purpose is to adjust the balance of the device so that during operation it does not outweigh either forward or backward.

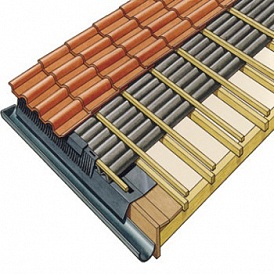

What nozzles (disks) are equipped with grinders

As noted above, the main cutting element of any grinder is a special high-strength removable disk. It is he who contacts with the treated surface and transfers the energy of the electric motor to it. At the same time, there are no universal discs, and various models suitable for working with a variety of materials can be found on the market. It is precisely depending on this parameter that one or another disk should be selected.

-

High-strength diamond wheels. Used for processing stone, marble, granite, as well as for metal cutting.

-

Korschtki - special nozzles, which are based on a rigid metal wire. Used to clean metal from plaque, corrosion and oxides;

-

Flap wheels are special soft discs designed for working with wooden surfaces, such as processing and polishing, and for the final stage of processing - polishing.

In the next article, our experts tell how to choose a punch.

Video on the choice of the grinder

Attention! This material is the subjective opinion of the authors of the project and is not a guide to purchase.