12 best substrates for laminate

One of the most popular flooring today is laminate flooring. Technology laying involves the use of a special layer, which is called the substrate. When buying laminate users pay minimal attention to this additional material, most often it is offered by the seller. But the quality of the substrate may depend not only on the durability and integrity of the flooring, but also the comfort in the room. What moments should pay attention?

How to choose a substrate for laminate

- Many Russian users, following the example of their neighbors, begin to care about their health and their relatives. Therefore, they prefer environmentally friendly building materials. On sale you can find products from natural raw materials (wood) or high-quality synthetic analogues. At this stage it is important to take into account the tendency of different people to allergies, the reaction to smells, etc.

- Thermal insulation. Laying the substrate can improve the microclimate in a particular room. First of all it concerns heat. Residents of private houses and apartments located on the first floor should choose the substrate, taking into account the insulating properties.

- Soundproofing. In a high-rise building, poor sound insulation becomes a serious problem. In order not to hear the noise in the apartment on the floor below, preference should be given to materials that absorb sound and vibration.

- Thickness. High-quality laying of the laminate is possible only on a flat surface. This is difficult to achieve on a screed or an old plank base. But with the help of the substrate it is possible to eliminate irregularities and floor drops. The worse the base, the thicker the layer is chosen under the laminate. Standard thickness is 3 mm.

- Moisture resistance. Modern flooring (laminate flooring) is quite sensitive to moisture. And if spilled liquids can be eliminated in a timely manner, high humidity from floor panels or screeds will cause the panels to swell. It is best to do a simple test for determining the moisture of the base, putting a plastic film overnight. If there is no perspiration in the morning, then the usual substrate will do.

- Manufacturer. As for the choice of manufacturer, today domestic brands compete on equal terms with import manufacturers. Some of them use foreign developments and technologies, someone introduces their own inventions.

Our review has got the best substrate for laminate. In compiling the rating, expert opinions and feedback from domestic consumers were taken into account.

Top laminate substrates rating

| Nomination | a place | Name of product | rating |

| The best substrate for laminate from natural materials | 1 | Steico underfloor | 4.9 |

| 2 | Premium cork | 4.8 | |

| 3 | PARCOLAG | 4.7 | |

| 4 | Tarkett Cork Underlay | 4.7 | |

| 5 | Isoplaat | 4.6 | |

| 6 | Arbiton cork | 4.5 | |

| The best substrate under the laminate of polymers | 1 | Eco-cover | 4.7 |

| 2 | ReFoam 3002 | 4.6 | |

| Best extruded polystyrene substrates | 1 | VTM, ISOPOLIN | 4.6 |

| The best polyethylene substrates | 1 | Tuplex | 4.7 |

| 2 | Foiled Isolon PPE | 4.6 | |

| 3 | Izolon PES | 4.5 |

The best substrate for laminate from natural materials

A whole set of advantages has a substrate of natural materials.Most often it is made from different components of wood (chips, chips, cork); natural or artificial resins and adhesives can be used to join small fractions. The only disadvantage of natural substrates is the high price. Experts have identified several high-quality products.

Steico underfloor

Rating: 4.9

The most environmentally friendly layer between the base and the laminate is the Steico Underfloor substrate. It is made from natural wood of coniferous species, individual fibers are fastened together using wood resin. The manufacturer offers its products in the form of rectangular plates measuring 790x590 mm, depending on the requirements of the homeowner, the substrate 3.6–7 mm thick is selected for the degree of thermal insulation. The material ranks first in the ranking for excellent properties, it is not afraid of moisture, ingress of solvent or glue.

Experts note good leveling abilities, the use of the product allows smoothing the height differences up to 3 mm. Users often use the material when laying laminate in children's rooms.

Virtues

- environmental friendliness;

- good leveling abilities;

- wide range of thicknesses;

- high performance.

disadvantages

- not detected.

Premium cork

Rating: 4.8

Premium Cork backing boasts high quality workmanship. In environmental friendliness, the material is not inferior to the leader of the rating, but the price of this natural product is quite high. The product is made from the bark of cork oak without the addition of chemical reagents. Experts point out that the cork substrate retains all the most important properties over time. This and excellent thermal insulation quality, the ability to absorb noise, leveling the floor. In a traffic jam does not settle pests, mold and fungus. Such a substrate will be particularly relevant for people suffering from allergies.

Users are pleased with the ease of preparation of the base. Dust and dirt are removed from the surface, after which the roll is rolled. Such packing for some builders is a minus.

Virtues

- environmental friendliness;

- long service life;

- good sound and heat insulation;

- simple base preparation.

disadvantages

- high price.

PARCOLAG

Rating: 4.7

A successful combination of natural and synthetic materials has PARCOLAG substrate. It is made on the basis of a dense cardboard, on which cork crumb mixed with bitumen is applied. The main advantage is thermal insulation. Experts recommend the product of the Russian company Icopal to owners of private houses and apartments on the first floor. With its help it is possible to put a reliable barrier to cold and moisture. The elasticity of the material increases the service life of the laminate.

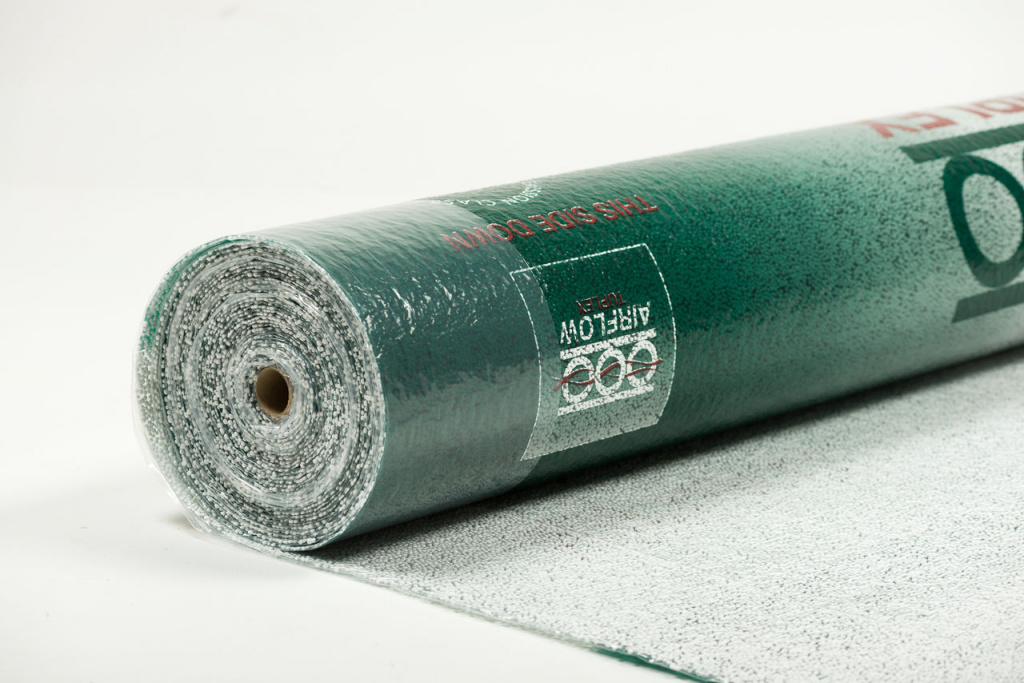

Due to the triple structure, there is good air exchange, therefore neither mold nor fungus appears in the substrate. In the trading network products come in rolls 15 mm long. Among the shortcomings, users note a stable odor of bitumen, so the applicant occupies the third line of the rating.

Virtues

- reliable heat and moisture insulation;

- good ventilation;

- elastic structure;

- high strength.

disadvantages

- not suitable for floor heating;

- smell of bitumen.

Tarkett Cork Underlay

Rating: 4.7

One of the most attractive prices for a natural substrate is offered by the Tarkett brand. The material is made from natural cork, which predetermines a number of positive moments. Polyurethane resin acts as a binder. First of all, the product is environmentally friendly, which expands its scope. The substrate quickly restores the original state after compression, and the good thermal insulation properties reliably retain the cold mass coming from the basement. On sale material can be met in the form of rolls 10 m long. The producer took care of fakes, it is possible to order a product on the official site. Of the shortcomings, users say a small range, the quality of the tube leaves much to be desired.

Virtues

- environmental friendliness;

- durability;

- affordable price;

- elasticity.

disadvantages

- thin layer;

- cork raw materials of poor quality.

Isoplaat

Rating: 4.6

In the production of an Isoplaat substrate, the main emphasis is on sound insulation properties. The material is made on the basis of sound insulation panels. It successfully combines natural ingredients and modern technology. Special fibers are formed from coniferous wood, which made it possible to obtain a porous structure. It is durable, and due to the introduction of antiseptics in the substrate does not multiply fungus and mold. The product can be purchased in the form of panels of size 850x590 mm. The maximum level of sound insulation can be achieved with a material thickness of 4-5 mm.

The advantages of the product users include the lack of smell, quality manufacturing. However, to find such material is not possible in every hardware store. Therefore, the applicant does not fall into the top three.

Virtues

- excellent sound insulation;

- elasticity;

- environmental friendliness;

- durability.

disadvantages

- shortage in the trading network;

- overcharge.

Arbiton cork

Rating: 4.5

The optimal ratio of quality and price is present in the Arbiton Cork substrate. The Polish manufacturer supplies products to the Russian market in the form of rolls (10x1 m). The required rigidity and thermal insulation for the floor covering is provided by a material 2 mm thick. Experts pay attention to the fact that the substrate can withstand temperature extremes. It is recommended for use in floor systems with warm (water) floors. However, it is required to lay shielding layers. The material is created on a natural basis, it has elasticity, leveling all the loads exerted on the laminate.

Builders praise the material for the formation of an even layer without waves. Only the edges of the material are fragile, so careful handling is required.

Virtues

- acceptable price;

- heat resistance;

- elasticity;

- no memory effect.

disadvantages

- fragility;

- heterogeneity of the composition.

The best substrate under the laminate of polymers

Synthetic substrates perfectly combine an affordable price and good performance. They create a reliable barrier to cold and moisture at the border of concrete and laminate. But the soundproofing capabilities of the composite material are limited. The experts selected several products.

Eco-cover

Rating: 4.9

The domestic Eco-cover is widely used. It is a product based on vinyl acetate and ethylene. Environmentalists have no claims in terms of material safety, therefore, it can be used both in office premises and in residential buildings and apartments. Experts point out excellent leveling abilities, and due to elasticity and high strength, the surface of the coating is tough. The product is produced in the form of plates, for ease of transportation, they are rolled into rolls.

The substrate becomes the winner of our rating for excellent technical characteristics. She successfully fights with noise, moisture, retains all of its qualities in a wide temperature range (-40 ... + 80 ° C). Finishers praise the material for ease of operation and a large selection of sizes.

Virtues

- wide scope of application;

- good noise insulation;

- moisture resistance;

- simplicity in work.

disadvantages

- high price.

ReFoam 3002

Rating: 4.8

One of the best indicators of noise insulation (21 dB) has a ReFoam 3002 substrate. The material is cross-linked polyethylene, which is safe for use in children's and medical institutions. Experts appreciate it for its high density and elasticity. Due to the combination of these qualities, the substrate is convenient in operation, and the floor covering is characterized by integrity. The production technology was invented in Japan, and products are manufactured and sold in Russia. The stores presented roll products (10x1.2 m), the optimum rigidity of the laminate is provided with a thickness of 2 mm.

The product is not the best water-absorbing ability, so it is not recommended to use it on the first floors of high-rise buildings, where there is a basement under the floor.The material occupies the second line of the rating.

Virtues

- good noise insulation;

- strength and elasticity;

- ease of transportation and installation;

- no smell.

disadvantages

- does not absorb moisture.

Best extruded polystyrene substrates

Extruded polystyrene is widely used in construction, it is made of it and the substrate for the laminate. The strengths of the material include price affordability and a wide choice in thickness.

VTM, ISOPOLIN

Rating: 4.6

The most affordable option for a laminate or parquet flooring device is the use of an extruded polystyrene substrate. Products are manufactured in the form of sheets that are conveniently transported and laid. ISOPOLIN is called a silent floor due to its good sound absorbing properties. The product stands out from the competition with a large assortment of thicknesses. The product has a low weight, which is why air flows often lift separate sheets from the floor. Experts advise immediately connect them with scotch tape.

Users are satisfied with the availability of material and ease of installation. The disadvantages include the fragility, modest leveling ability of thin sheets (less than 3 mm).

Virtues

- low price;

- ease of transportation and installation;

- small weight;

- Suitable for all bases.

disadvantages

- fragility.

The best polyethylene substrates

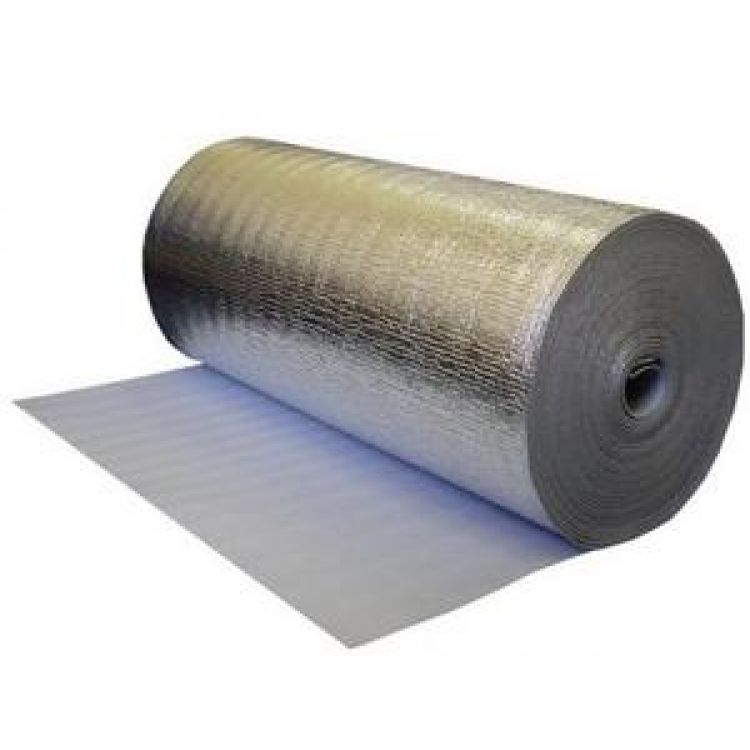

Polyethylene backing is very popular with Russian users. The material is resistant to microorganisms, moisture, it is easy to use. To improve the heat and waterproofing properties, manufacturers supplement polyethylene foam with aluminum foil. Here are some quality products.

Tuplex

Rating: 4.7

The unique Finnish technology is implemented in the Tuplex polyethylene substrate. Between the two films are balls of foam. Moreover, the bottom layer has a special perforation, which allows moisture to penetrate into the material. Water is released along with air flows through the edges of the substrate. It is clear that we are talking about a small amount of moisture. Otherwise, the material will start a mold or fungus.

According to experts, such a breathable design is easy to install. There is a small percentage of waste, which is inherent to other competitors. For good technical parameters and original design, the substrate becomes the winner of our rating.

Virtues

- unique manufacturing technology;

- good moisture absorption;

- breathable design;

- effective ventilation.

disadvantages

- limited thickness range.

Foiled Isolon PPE

Rating: 4.6

At the same time, foil Izolon PES allows to protect the floor from cold and moisture. The substrate is a cross-linked polyethylene, which is produced in rolls. Aluminum foil is attached to the substrate on one side. Thanks to this design, the material has a low coefficient of thermal conductivity. The material perfectly protects the laminate from steam and moisture, often foil Izolon used as a waterproofing. Along with durability and resistance to rotting, the product has environmental safety. It is suitable for installation of heated floors.

When laying laminate there is a problem with the formation of a solid layer. As a result, the joints become weak places for the penetration of cold and moisture.

Virtues

- low thermal conductivity;

- security;

- elasticity;

- reusability.

disadvantages

- high price.

Izolon PES

Rating: 4.5

Owners of apartments living above the 2nd floor, when laying laminate or floorboard, can use Izolon PES as a layer.In contrast to the foil version, the material does not claim to be the best insulation or vapor barrier. This is not required of him when the flooring is mounted on a dry and warm floor. The basis of the substrate is the same foamed polyethylene, stitched into a single roll. Due to the multi-layered cellular structure, the product perfectly absorbs noise and vibration, additionally preventing heat losses in the room. Experts note the inertness of polyethylene foam, it does not emit harmful compounds, does not react with gasoline or alkaline-based detergent preparations. A set of useful characteristics allows the substrate to take third place in our ranking.

Virtues

- affordable price;

- inertness;

- good noise insulation;

- security.

disadvantages

- gradual thinning of the substrate.

Attention! This rating is subjective, is not advertising and does not serve as a guide to the purchase. Before buying, you should consult with a specialist.